(单词翻译:单击)

If you were to track the upgrades for your Apple iPhone or Toyota Prius from their introduction to today, you will see a familiar arc in the technology industry: performance multiplies, the product is refined, jobs are created, even entire industries are reworked.

如果回顾一下苹果公司(Apple)的iPhone或丰田(Toyota)普锐斯(Prius)混合动力车从最初型号到现有版本的发展过程,人们会发现技术行业一个常见的轨迹:性能翻倍提升,产品更精致,创造了无数就业岗位,甚至颠覆了整个行业。

Consider, for example, that the iPhone’s theoretical maximum download speed on cellular networks went from 1 megabyte per second for the 2007 “2G” iPhone to 300 mbps for today’s 5s model. Its display more than doubled in pixel density, its camera transformed from cheap afterthought to serious photography tool, and its software capabilities are far more robust than when the device was introduced. (Even the App Store is a second-generation feature.)

例如,iPhone在蜂窝网络中最大的理论下载速度已从2007年“2G”iPhone的1兆字节/秒上升至如今5s型号的300兆字节/秒。其显示屏的像素密度增加了一倍多,摄像头已从廉价的配件转变为一种实用的照相工具,而且其软件能力要比iPhone诞生之时强大太多太多。(即便是苹果应用商店如今也已发展到第二代了。)

Similarly, Toyota’s Prius hybrid car evolved from a neighborhood oddity (and celebrity eco-accessory) in 2000 to a best-selling vehicle in Japan and California. The engine in today’s model is 20 percent lighter (and offers 20 percent more total horsepower) than the original. Its distance-per-charge is longer. Without the Prius, it can be argued, there would be no Tesla.

同样,丰田的普锐斯混合动力车从2000年的邻家怪胎(以及明星彰显其环保态度的配饰)摇身一变为日本和加州最畅销的交通工具。当前车型引擎的重量较最初型号轻了20%(总功率增加了20%),而且单次充电后行驶的里程更长。有人会说,没有普锐斯,就不会有如今的特斯拉电动车(Tesla)。

There’s is one component of all of these things that hasn’t changed in that time period: the lithium-ion battery. Whether in the iPhone, the Prius, and even the Tesla Model S, the Li-ion battery is essentially made of the same stuff as those first introduced by Sony in 1991. That’s not to say that innovation hasn’t happened around them, of course. Device-makers have become better at charging them, cooling them, and controlling how much power they draw into our phones, cars, laptops, and USB gadgets. But they’re still largely the same battery. Even Tesla’s $5 billion plans for a “giga”-sized battery factory involve the manufacture of—you guessed it—lithium-ion packs.

然而在这些设备中,有一个组件这些年来一直没有变化,那就是锂离子电池。不管是在iPhone,还是普锐斯,甚至是特斯拉S车型,锂电池用的还是1991年索尼公司(Sony)推出这一产品时所用的材料。当然,这并不是说人们没有针对这种电池进行过创新。设备制造商在充电效率、冷却和控制进入手机、汽车、笔记本和USB元件的电流流量方面做得越来越好,但这些电池的芯却没有怎么换过。即便是特斯拉计划建造的50亿美元超大型电池生产厂生产的仍是(如你所料)锂电池组。

Upon further investigation, there is little consensus on what kind of battery technology may replace lithium ion. There aren’t even rumors.

进一步的调查发现,人们对于哪一种电池技术可能能够取代锂电池仍是众说纷纭,甚至连这方面的谣言都是寥寥无几。

To find out why, Fortune posed a simple question to five established researchers working on next-generation batteries, a behavioral economist, and a battery industry executive: Why is battery technology moving so much slower than hardware?

为探究其原因,《财富》(Fortune)向致力于开发下一代电池的5名知名研究人员、一名行为经济学家和一名电池行业高管提出了一个简单的问题:为什么电池技术的发展速度要比硬件慢如此之多?

As you’ll soon find out, the answer is one part chemistry, one part psychology, and two parts the answer to a counter-question: Who really wants to be the first to drive with a new type of battery that hasn’t benefited from two decades of development?

接下来你便会发现,答案的一成与化学有关,一成与心理学有关,而两成则与上述问题的反问有关:对于一项未经过二十年发展的新电池技术,一旦装上汽车,谁想成为首位驾驶该车的人?

Today’s battery tech: dense, hot, tricky

当今的电池技术:密度大、发热量大、问题多

Lithium-ion battery technology is in many ways the workhorse of portable power.

锂离子电池技术在很多方面都是移动电源的主力军。

Lithium’s atomic number is three, which, if you remember middle-school chemistry, means that it has three protons, is very lightweight, and can be packed more densely than any element other than hydrogen or helium. Lithium is a known quantity to chemists, says Carlo Segre, professor of physics at the Illinois Institute of Technology in Chicago, and we mostly understand how it flows inside a battery.

锂的原子量是3,如果你还记得中学化学的话,这意味着它有三个质子,非常轻,是除了氢和氦之外单位体积可填充密度最高的元素。芝加哥伊利诺伊州理工大学(Illinois Institute of Technology)物理学教授卡洛o塞格雷表示,锂的物理量为化学家们所熟知,我们几乎掌握了锂离子在电池中流动的方式。

“I think it really boils down to, the reason lithium is so good, is that it’s very light, and you can get it through a membrane very easily,” Segre says. “And the potential difference (voltage) you can generate is one of the highest we know.”

塞格雷说,“我认为归根结底,锂如此好的原因在于,它非常轻,而且能够轻易地穿透隔离膜。而且其产生的电压是已知材料中最高的之一。”

It’s not just lithium that goes into a Li-ion battery. The element gets mixed with magnesium (for personal gadgets and vehicles), iron phosphate (for heavy-duty work), and other metals. That mixture flows into another material to create voltage: graphite, titanium solutions, silicon, and different forms of carbon, depending. In most non-industrial devices used in relatively safe conditions, you have lithium manganese oxide flowing into graphite, because those materials are cheap, relatively safe, and dense.

锂并不是锂电池里的唯一材料,其中还混有锰(个人电子产品和交通工具)、磷酸铁(高强度工作)和其他金属。为了产生电压,这种混合物会流经另一种材料:石墨、钛溶液、硅和不同形式的碳(依情况而定)。对于大多数在相对安全的环境中所使用的非工业设备来说,流经石墨的是锂锰氧化物,因为这种材料价格低廉,相对安全,而且密度高。

But there are quite a few problems with the old faithful. The process generates heat in a dense space, requiring some kind of cooling system. (A tremendous amount of work went into Tesla’s car-length liquid cooling rig, for example.) The electrolyte that conducts lithium’s flow adds weight. The cells lose their capacity over time. Charging the battery, which makes the lithium flow back, could be quicker. And though it’s rare, we have seen that tightly packed batteries full of fluids, made very hot, can sometimes puncture or explode.

但是这一老产品也存在一些问题。这一进程会在一个高密度空间内产生热量,需要采取一些冷却措施。(例如,与特斯拉车身长度相当的液态冷却设备担负了大量的冷却工作。)传导锂离子的电解液增加了电池的重量。电芯的容量在一段时间后就会下降。充电会让锂离子回流,但这一进程可以更快一些。充满电解质的高密度锂电池在发热量超过一定程度之后有时会爆浆或爆炸,虽然这一情况很少见。

What we might use next: air

今后我们可能会使用空气

Chandrasekhar “Spike” Narayan, director of science and technology at IBM Research, is part of the Battery 500 Project. The goal is to get batteries to power a car of average cost on a 500-mile trip. IBM won’t build the batteries itself, but will partner with manufacturing and consumer companies to get them into the wild.

IBM研究院(IBM Research)科技部主任钱德拉塞卡尔o纳拉延是电池500项目(Battery 500 Project)的成员。该项目的目标是,开发能够提供行驶500英里路程所需电量的电池。IBM公司自身并不会生产电池,而是与消费类产品制造商开展合作,将这一技术带到现实中。

After years of work, Narayan sees a future for lithium-air technology, which replaces graphite and other metals with oxygen, refreshed by the car itself. Such batteries could be lighter, safer, and last far longer. But working with new mixtures, pushing them into new materials, and seeing how safe they are over thousands of charge cycles takes a very, very long time.

经过多年的努力之后,纳拉延看到了锂-空气技术的前景,即用汽车自身补给的氧气取代石墨和其他的金属。这类电池可以变得更轻,更安全,而且供电时间也更长。但是研发新的混合物,将它们制成新材料,并检测其在数千辆汽车上的安全性,需要花费非常漫长的时间。

“There is no guiding principle that suggests you get improvement from year to year,” Narayan says. “There is no magic knob you can turn. The only way we can get to that kind of paradigm is a completely new kind of chemistry, and innovation doesn’t work like that.”

纳拉延说:“目前没有一个指导性原则显示,我们能够年复一年地获得进步,也没有捷径可以走。要得到这种范式,唯有创建一种全新的化学反应,而这一点并非创新所能企及的。”

Currently, lithium-air batteries have to overcome problems with blockages, internal rust, and stability. Even if air batteries are smoothed into a viable product, Narayan sees a future where battery technology is no longer one-size-fits all. “It may not be a great technology for power grid storage, for example. Especially when there is a size requirement, we may see differentiation among battery types soon.”

当前,锂-空气电池必须克服堵塞、内部腐蚀和稳定性问题。即便空气电池能够顺利地演变为一种可行产品,纳拉延认为,在今后,电池技术将不再是“通用型”。“例如,对于电网存储来说,它或许不是什么好技术。尤其是有尺寸要求的行业,我们或许很快将看到多种多样的电池类型。”

What we can do in the meantime: get cheaper

当前我们能做些什么:降低价格

Kevin Bai and Xuan “Joe” Zhou at Kettering University work in labs and in battery industry research, but they talk like car shoppers than laboratory wonks. With the hybrid vehicles of today, Zhou notes, there are lots of trade-offs, in several ways.

凯特林大学(Kettering University)的凯文o白和周轩(音译)在实验室中从事电池行业研究,但他们的谈吐更像是买车人而不是实验室的书呆子。周轩表示,现今的混合动力车存在多方面的优缺点。

“Right now [hybrid] batteries are selling for $500 to $600 per kilowatt hour, but they should be $200,” Zhou says. “And every dollar you spend in the battery is another dollar in cooling. If the car needs a $6,000 battery, it’s a $6,000 cooling system.” What’s more, Bai notes, the size of such a battery eats up trunk or seating space. The scientists agree that an electric vehicle should feel like less of a financial albatross.

周轩说:“目前,混合动力的售价是每千瓦时500-600美元,但合理的价格应该是200美元。而且冷却系统的价格跟电池的价格是差不多的。如果汽车需要6,000美元的电池,那么就需要6,000美元的冷却系统。”此外,凯文o白指出,这类电池的体积蚕食了本应属于后备箱或乘坐的空间。两位科学家也认为,电动汽车不应给人们带来沉重的财务负担。

But it’s anybody’s guess as to which current materials may work out to have the safest, coolest, and most lightweight mix, while still selling for less than today’s offerings.

但是谁也不知道,哪些现有材料才能构造出最安全、发热量最低和重量最轻的电池混合材料,而且其价格要比现有的产品便宜。

Zinc-air batteries, used in hearing aids today, are seeing renewed interest, especially given zinc’s easy availability. The same goes for sodium-air, which are cheaper and easier to assemble, if not as potentially powerful as lithium-air. There are also attempts to replace the graphite and carbon solids in batteries with silicon, though silicon isn’t cheap. Or we might just improve the cost and performance of the lithium-iron batteries in our drills and motorcycles in the meantime.

现今在助听领域使用的锌-空气电池重新激起了人们的兴趣,而且尤为重要的一点在于,锌很容易获取。钠-空气电池也是一样,成本更低,而且组装起来更容易,只是潜在功率赶不上锂-空气电池。人们还尝试过用硅来取代石墨和固体碳,但是硅并不便宜。或者,我们可以只专注于改善实验室和摩托车使用的锂-铁电池的成本和性能。

In many ways, Bai says, building larger battery plants, better battery management tools, and a smarter power grid for charging is going to bear greater fruit than waiting on one or another chemical combo to pay off.

凯文o白表示,建造更大规模的电池厂、开发更好的电池管理工具以及更加智能的充电电网在很多方面要比等待一两项新化合物获得成功更为实在。

“We are actually very far away from a brand-new battery for vehicles,” Bai says. “The automotive industry, they must feel they can stand behind 10 years of testing before they are comfortable trying a new material.” It will be at least 2020, he says, before you see zinc-air batteries in the first four-wheeled vehicles–and then a long while more before that battery technology matures.

凯文o白说:“我们实际上离使用全新电池的交通工具还很远很远。只有在新材料经过10年的测试之后,汽车行业才能放心使用新材料。”他表示,人们至少要等到2020年才能看见使用锌-空气电池的四轮车辆,然后,人们需要更长的时间才能看到这一电池技术的成熟。

What we can do in the future: nano-engineer materials

未来我们能做什么:纳米工程材料

Don’t give up on lithium-ion just yet, says Partha Mukherjee, a professor at Texas A&M University and leader in the American Society of Mechanical Engineers’ Nanoengineering for Energy and Sustainability group. We might still be using it, but with materials that have gained some new powers in the lab.

德克萨斯农工大学(A&M University)教授、美国机械工程师协会(American Society of Mechanical Engineers)能源和可持续性纳米工程小组成员帕沙o穆克荷吉表示,现在还没到放弃锂离子电池的时候。我们可能仍会用它,但它将与我们在实验室中获得新能力的材料混合使用。

Nanoengineers might dig into the molecular structure of battery materials to speed up how they transfer more voltage per cell. There might be a change in the way the electrolyte conveys lithium ions so that “traffic jams” don’t occur and charging is much faster. You could design a thinner, stronger, but still flexible membrane for batteries that allows for swelling under heat but never breaks. Or go for broke and develop a material that absorbs more lithium ions than carbon, air, or any material we know.

纳米工程师可能会对电池材料的分子结构进行深入研究,以加速电池单元电压的产生速度,并提升其转换效率。电解质携带锂离子的方式可能会发生改变,以杜绝“交通拥堵现象”,并缩短充电时间。人们可能会设计出更薄、更强大但伸缩依然自如的电池膜,这样,即便电池受热膨胀,也不会爆浆。或者一心一意开发能够比碳、空气或任何已知材料吸附更多锂离子的材料。

“The fundamental question we need to ask is, ‘How about starting from the bottom up?” Mukherjee says. “That is the mesoscale paradigm that must be addressed. Can we make materials that are more tolerant of what we need batteries to do?”

穆克荷吉说:“我们需要询问的最根本的问题在于,‘是否可以从头再来?’。这就是必须解决的中尺度模型。我们是否能增加材料的宽容度,以满足我们对于电池的诉求?”

In the meantime: get perspective

与此同时:着眼于长远

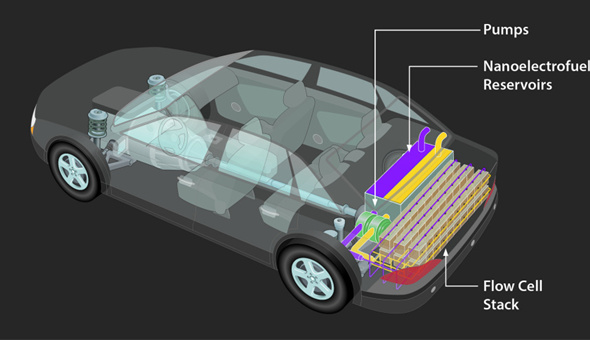

A year ago Segre, of the Illinois Institute of Technology, received a $3.4 million prize from the U.S. Department of Energy to develop a “flow battery” for car applications. Flow batteries store their active chemicals in external tanks and pass it through the battery structure itself. Segre’s work focuses on developing a liquid that is reactive and powerful enough to compensate for the liquid weight trade-off.

一年前,伊利诺伊理工大学的塞格雷从美国能源部获得了340万美元的奖金,用于开发汽车用“流体电池”。流体电池将其活性化合物储存在外部储罐中,然后流经电池结构内部。塞格雷的工作专注于开发具有足够活性和能量的液体介质,以抵消液体的重量劣势。

A flow battery might work in cars and power grid applications, but it will never work for a phone or laptop. Segre, like most researchers, knows it will be a long series of experiments until researchers hit upon a few different material combinations for batteries. In the meantime, “It’s especially frustrating for most of us because the battery dies, the capacity drops, after a couple years, while the electronics it powers could go on and on.”

流体电池或许可以应用于汽车和电网,但却无法适用于手机或笔记本。与其他的研究人员一样,塞格雷深知,这将是一个漫长的实验过程,除非研究人员能够在偶然间发现几种能用于电池的不同材料组合。与此同时,“对于大多数人来说,这是一件尤为痛苦的事情,因为几年过后,电量没了,容量也下降了,然而电池供电的电子产品却在不断前进。”

For decades, we lived within Moore’s Law, which predicted that the number of transistors packed into a processor would double every two years, providing a steady gallop of technology improvement. We are now approaching a point at which transistors are near atomic-scale, chips can’t fit many more processors, and we’re unhappy with having the same kinds of batteries in our devices.

过去几十年中,我们一直生活在摩尔定律(Moore's Law)当中。根据该定律,处理器中的晶体管数量每两年会翻一番,而这也说明了技术进步的稳定性。我们目前所面临的局势是,晶体管尺寸已接近原子水平,芯片无法容纳更多的处理器,而且我们对设备中一成不变的电池感到不满。

In other words, when it comes to physics, there’s no app for that. Which can be a bitter pill for tech-savvy consumers to swallow as they become acclimated to regular advancements in every other part of their electronic devices, says Michal Ann Strahilevitz, a professor of marketing at Golden Gate University.

换句话来说,物理中是没有应用程序的。金门大学(Golden Gate University)市场营销教授米盖尔o安o斯特拉赫维茨表示,这对于深谙技术的消费者来说可能有点难以接受,因为他们已经习惯了电子设备每一部件都会定期改良。

“Adapting to upgrades is easy, and the more you are upgraded, the more you expect further upgrades,” Strahilevitz says. “In a world where [gadgets] keep getting better and more efficient, we feel we have a right to that. We ask, ‘Why can’t they be more wonderful than this?'”

斯特拉赫维茨说:“适应升级很容易,得到的升级越多,对进一步升级的期望也就越大。在这个电子产品越来越好,性能越来越高的世界中,我们觉得这是我们应享有的权利。我们会问,‘为什么电池不能变得更好呢?’”